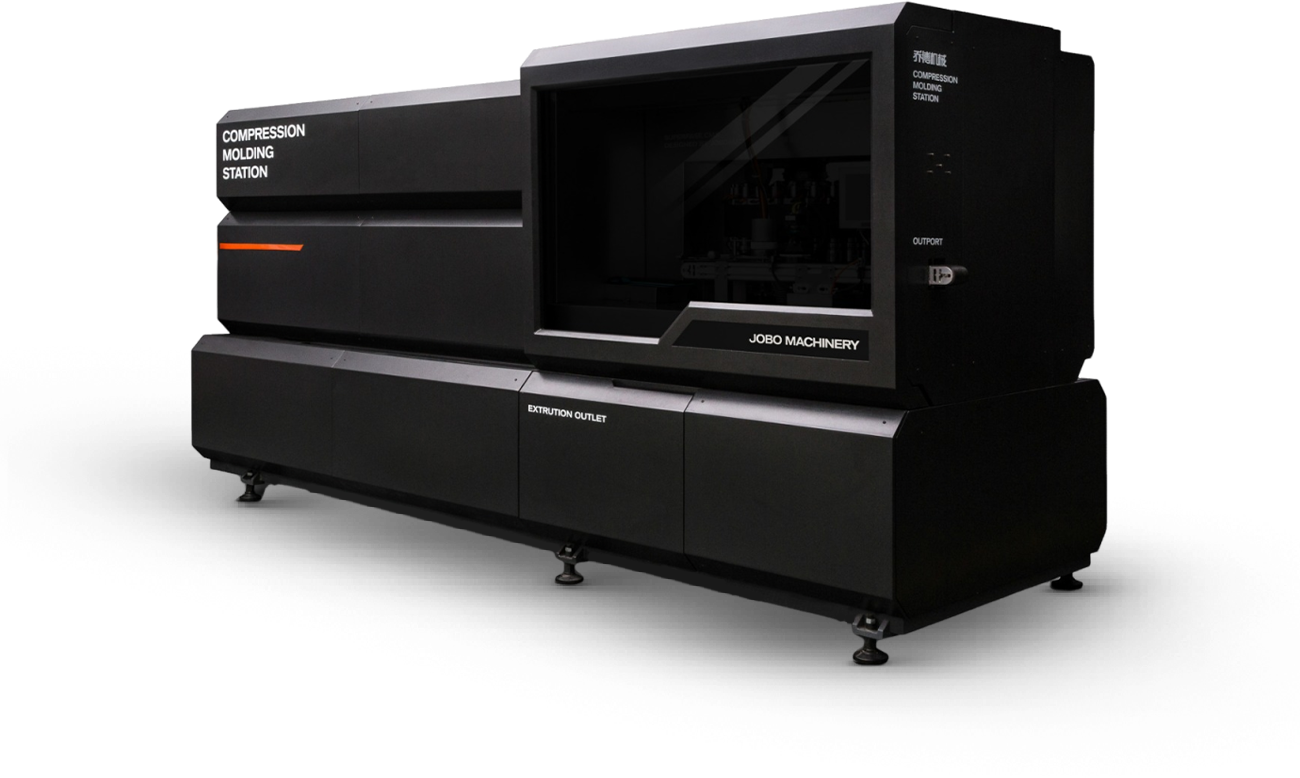

Plastic Cap Making Machine

Jobo India is a trusted name in the field of Plastic Cap Making Machine, known for their expertise in Cap Compression Molding since 1988. As the official partner of Jobo Machinery (China), we deliver Plastic Cap Making Machines backed by over a decade of international expertise. Our main focus is on providing high-performance, energy-efficient, and cost-effective Plastic Cap Making Machine to meet the needs of modern manufacturers in businesses like packaging, beverages, pharmaceuticals, cosmetics and many more.

HOW THE PLASTIC CAP MAKING

MACHINE WORKS?

The Plastic Cap Making Machine works by first heating plastic resins into a semi liquid form. Then cutting the pellets by material cutter and dropping them into a Mold cavity. The plastic is then compressed and shaped by the Mold, after which it is cooled and ejected. Unlike injection Molding, the Compression Molding is faster, and consumes less energy—making it a popular choice for modern cap manufacturers.

Here’s how the process works, step by step:

Heating the Plastic:

Small plastic resins—usually made of HDPE or PP—are first heated inside the Plastic Cap Making Machine until they reach a soft, semi-molten state.

Quantified Dropping:

Once the plastic is ready, a measured amount of molten plastic is cut by material cutter and dropped into each Mold cavity with the help of Air. This ensures consistent cap size and weight to be manufactured in the Plastic Cap Making Machine.

Compression Molding:

Once the plastic is dropped into the cavity, the Mold then closes. The Plastic Cap Making Machine compresses it under high pressure to form the exact shape of the cap. This step gives the cap its final design, including threads and seals.

Cooling the Mold:

After compression, the Mold is cooled using water-cooling system so the cap can solidify properly while it remains in the Mold cavity. The Plastic Cap Making Machine controls the cooling time carefully to maintain cap quality..

Cap Ejection:

Once the cap is fully formed and cooled, it’s gently ejected from the Mold ready for post Molding process.

Repeat Cycle:

This entire process is repeated in a continuous rotary motion, allowing the Plastic Cap Making Machine to produce thousands of caps per hour with minimal waste and high consistency

This compression technology not only improves speed and quality but reduce raw material wastage and power consumption. That’s why many leading cap manufacturers around the world rely on the Plastic Cap Making Machine to upgrade their production lines.

Plastic Cap Making Machine

If you are looking for a reliable and high-performance Plastic Cap Making Machine, you are in the right place. Our Plastic Cap Making Machine is designed to deliver speed, accuracy, and quality for cap manufacturers in the beverage, water, dairy, and pharmaceutical industries

Our Plastic Cap Making Machine helps you produce caps with perfect shape, tight seal, and consistent quality, using advanced compression Molding technology. Unlike traditional injection systems, this Plastic Cap Making Machine saves energy and raw material, you can expect up to 53,000 caps per hour with our Plastic Cap Making Machine, depending on the model and cap type.

Features of Our Plastic Cap Making Machine

Our Plastic Cap Making Machine is fully automatic and easy to operate. Whether you use HDPE, PP as your raw material, the Plastic Cap Making Machine is built to handle it efficiently. Each Plastic Cap Making Machine is designed to be durable, low-maintenance, and suitable for 24/7 production run

We offer different models of the Plastic Cap Making Machine to match your specific needs—be it size, shape, or cap application. All Plastic Cap Making Machines come with installation support, operator training, and after-sales service..

The Right Plastic Cap Making Machine for Growing Businesses

The Plastic Cap Making Machine is a smart investment for any cap manufacturing business aiming to grow with quality and reliability. The Machine supports mass production while reducing downtime and operating costs for your production line. If you're planning to expand or upgrade your manufacturing unit, our Plastic Cap Making Machine will be the perfect choice.